ANTI-SEIZE SA 610:

The Advanced Solution for High Temperature Superalloys

ROCOL offers a wide range of Anti-Seize and assembly solutions designed to meet the needs of various industries. Whether you are working with aerospace turbines, chemical processing systems, or pressure vessels, ROCOL has developed products that are reliable and optimised for specific applications. Within this range, the ANTI-SEIZE SA 610 is an advanced solution optimised for extreme temperatures and high-performance alloys, meeting the critical needs of power generation, aerospace, and other industries.

Interested in experiencing the benefits for yourself? Please reach out to explore trialling our product and request free samples.

Independently validated by Siemens Energy:

What a Good Anti-Seize Does

Anti-Seize compounds protect metal surfaces, reducing friction, aiding assembly, and ensuring that components remain serviceable over time. A superior product not only prevents seizing and galling but also ensures ease of disassembly even after extended exposure to extreme heat, chemicals, or pressure.

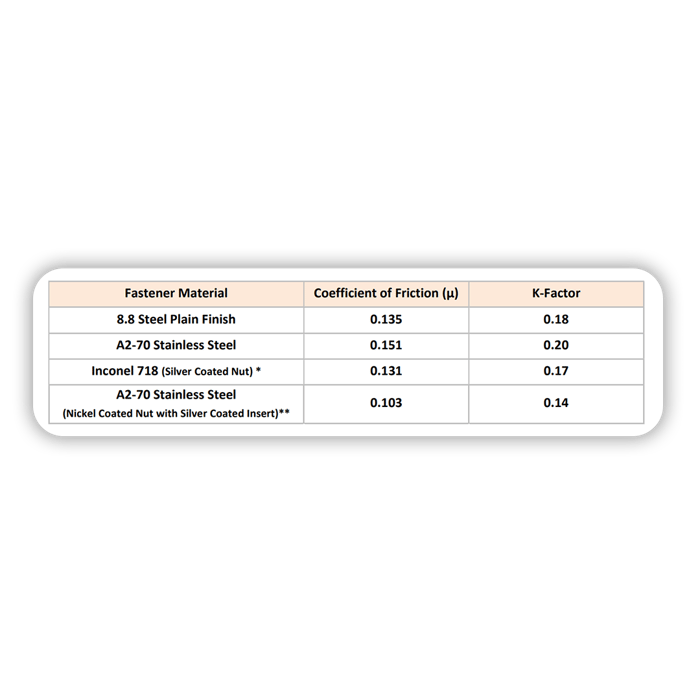

Precision Assembly - Torque Tables

Torque tables are critical for ensuring precise assembly in high-performance industries. These tables, often established company-wide or for specific designs, are costly and complex to change.

Torque tables should not be generalised, as the required torque varies depending on factors like the lubricant used, the material, and the thread type.

For ROCOL products, torque setting data is provided in the Technical Data Sheets (TDS), enabling customers to follow best practices.

Determining the correct torque to achieve the required tension involves understanding the K-factor and the Coefficient of Friction formula. These formulas help engineers determine the correct torque for precise tensioning.

The selection of the most suitable Anti-Seize product depends on factors such as the fastener material, the operating temperature, and whether the application is static or dynamic.

Best Practice

Using the right Anti-Seize in the correct quantity is essential for optimising assembly and disassembly processes.

Best practice dictates that the surfaces be clean and degreased before application, and a thin, even layer of Anti-Seize should be applied to ensure optimal performance. Over-application can lead to excess lubricant being forced out under pressure, which could impact the assembly’s effectiveness.

ANTI-SEIZE SA 610

ANTI-SEIZE SA 610 is ROCOL’s advanced Anti-Seize solution specifically designed for high-temperature superalloys and stainless steel fasteners used in demanding environments.

Unlike traditional compounds, SA 610 does not contain metal powders or calcium, making it ideal for applications where health and safety, environmental or operational factors restrict the use of such materials.

Anti-Seize SA 610 has been optimised to provide consistent friction and release properties even after exposure to extreme temperatures. It has been tested across a range of fastener materials, including:

🔶Inconel 718

🔶Stainless Steel

🔶Waspaloy

🔶Silver-coated high temperature fasteners

This makes it the perfect choice for critical applications in industries like power generation and aerospace. Its superior formulation allows it to perform consistently even after exposure to extreme temperatures, ensuring precise tensioning and controlled release during disassembly.

Consistent coefficient of friction to ensure precise tensioning during assembly

Key Features of ANTI-SEIZE SA 610

Anti-Seize SA 610 is especially suited for critical applications where the need for precision is paramount. These include:

- Turbines (both ground-based and aerospace)

- Aerospace assemblies

- Flange joints in chemical and processing industries

- Pressure vessels exposed to high temperatures

These applications require a high-performance Anti-Seize compound that can withstand extreme conditions while ensuring the integrity of the assembly.

🔶High Precision in Assembly

The high precision required in these critical industries means that even a minor deviation in the coefficient of friction can have significant consequences.

Anti-Seize SA 610 ensures that components are assembled with the correct tension, minimising the risk of failure and reducing the likelihood of expensive repairs or downtime.

🔶Extremes of Temperature

In industries such as power generation and aerospace, components are routinely exposed to extreme temperatures.

SA 610 is formulated to maintain its protective properties across a wide temperature range, from -40°C to +1000°C, making it one of the most versatile anti-seize solutions on the market.

🔶High Cost of Failure

The failure of critical components in these industries can result in damage, significant financial losses, and safety risks.

Using a high-performance Anti-Seize like SA 610 helps to mitigate these risks, ensuring that assemblies remain secure and reliable over their operational lifespan.

Hexavalent Chromium (Cr(VI)) Control

At elevated temperatures, the oxidation of high temperature alloys can cause changes in the chromium phases of the alloy.

The presence of calcium has been associated with the retention of hexavalent chromium, (CrVI), in residues of anti-seize compound and thermal insulation. As such, calcium is prohibited for high temperature use with chromium-containing alloys.

Anti-Seize SA 610 does not contain calcium. It has been independently tested to confirm that residues generated in contact with chromium containing alloys retain negligible levels of Cr(VI).

Frequently Asked Questions

What makes Anti-Seize SA 610 suitable for high-temperature applications?

Anti-Seize SA 610 is specifically formulated to maintain performance in extreme temperatures, ensuring the reliability of components and minimizing downtime.

Is Anti-Seize SA 610 compatible with all types of fasteners?

Yes, it is compatible with a wide range of materials including stainless steel, Inconel, and high-temperature superalloys.

Does Anti-Seize SA 610 contain any hazardous materials?

No, it is calcium-free and has been tested for safety, particularly regarding Cr(VI) retention.

Who has verified the performance of Anti-Seize SA 610?

Siemens Energy has independently validated its friction, release, and Cr(VI) retention properties.